The weight of your parcel is calculated using two different methods that will determine the cost of your delivery: dimensional weight and actual weight. By reducing the dimensions of your parcel and packing it right, you can save on shipping costs. In this article we tell you how! But first, we must understand what the difference is between dimensional weight and actual weight.

What is Dimensional Weight versus Actual Weight?

Dimensional weight and actual weight are two methods used to calculate the billable weight for a shipment.

Actual weight is the package's weight rounded up to the next kilogram. A package that weights 6.6kg would have an actual weight of 7kg.

Your billable charge will be the greater of the two, actual or dimensional. If the actual weight of your parcel is 7kg but the dimensional weight is 5.5kg you will be charged at the greater weight of 7kg.

Dimensional weight takes into consideration the density of a package. This is the amount of space a package occupies compared to the actual weight.

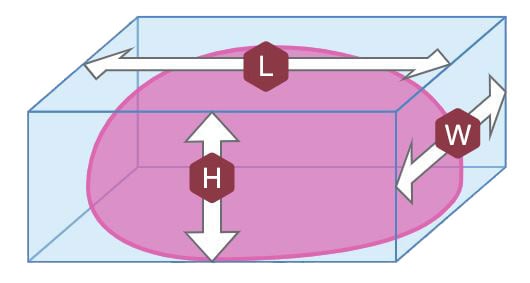

When you book a delivery through our website you need to indicate the length, width and the height of the parcel. These measurements will allow us to calculate the dimensional weight and compare it to the actual weight which you also indicate when booking with us.

Dimensional Weight = (Length x Width x Height) ÷ divisor

Some carriers may indicate the billable charge in volumetric or dimensional weight for calculation of your freight charge. This is done as they are charging you not only for your package's weight, but for the space your package takes up in their truck or aircraft. When calculating dimensional weight, most shipping carriers request that you round up to the nearest whole number.

Understanding how carriers determine the billable weight

One of the main issues determining dimensional weight is understanding the systems used by carriers to calculate these charges.

Many large courier companies use automated (in-line) conveyor systems that calculate the actual weight and the dimensional weight.

These automatic systems provide the dimensions and actual weight of your shipments quickly and without human intervention. The automated devices measure the largest dimension on each axis without taking into account if it is an actual part of the box; a fat packet of documents, bulging flap or an irregular shape all add to the dimensions calculated.

While it is important to keep the size of the carton to a minimum, it is also important to find boxes that fit the item to be shipped properly. If an irregular item is presented to most carriers, they will calculate the dimensional weight based on the largest measurements obtained by the automatic dimensioning systems. This information is then uploaded into the carriers billing system and used to determine the billable weight for invoicing. We show you the right method to measure your shipping box:

- Length measurement needs to be taken where the item is longest

- Width measurement needs to be taken where the item is widest

- Height needs to measure from the bottom of the item to its highest point (including the pallet or skid the items are on)

Freight and courier drivers rely on knowing the sizes and weights of their cargo to be able to plan and carry out deliveries as safely and efficiently as possible. In addition, giving the correct size and weight information helps us provide you with an accurate quote, delivery time, and allows the carrier to allocate an appropriate vehicle for transportation.

How to reduce shipping costs

Smart shippers need to pay attention to dimensional weight. It can make a huge difference in your shipping costs. If you don't consider dimensional weight, you could easily run into over or under charges.

Another thing to consider is that when you use a box that is too large, not only will you pay more based on the dimensional weight, but you're also more likely to experience issues with damaged goods. If items are packed loosely, they are more likely to shift and get damaged in transit. You may also end up paying more for the actual packaging as larger boxes typically cost more and you'll need to use additional filler material.

- Reduce your box size: Try to pack items as compactly as possible. If you're filling half of the box with foam packing or airbags, then you're likely overpaying to ship the item.

- Use polybags or padded envelopes: Where possible, use polybags or padded envelopes to ship non fragile products.

- Use a live shipping calculator at checkout: For e-Commerce businesses we recommend integrating a live shipping calculator at checkout which enables you to display accurate delivery costs to your customers. The Interparcel Smart Boxing feature can help reduce your costs by helping you pack multi item orders efficiently. You define your box sizes and our algorithm will combine products into as few boxes as possible.

- Import - Request the shipper to provide the exact measurements: Reach out to your shipper and request they provide exact weight and dimensions - not approximates, be precise and clear when requesting this information to avoid extra costs. One of the main concerns from an importer's perspective is, you can view the item you have purchased but you can't see the external packaging it's being sent in.

If you have any queries regarding your shipments and how to determine the correct billable weight, contact us here!

Facebook

Facebook Twitter

Twitter Instagram

Instagram Linked In

Linked In YouTube

YouTube