You may not realise it, but every ecommerce business already uses a picking method.

Whether you are packing orders from a spare room, a small warehouse, or a growing fulfilment space, how you pick products plays a big role in how quickly you ship, how accurate your orders are, and how easily your business can scale.

You might not know what kind of picker you are yet. But by the end of this guide, you will.

This guide breaks down the most common warehouse order picking methods, explains when each makes sense, and helps you decide which approach best suits your business, especially since picking orders is one of the most time-consuming parts of ecommerce fulfilment.

Let’s dive in and start with the basics...

What Is Order Picking?

Order picking is the process of locating and collecting products from storage so they can be packed and shipped to a customer.

Every time an order comes in, someone (or something) needs to find the right items, in the right quantities, and move them through to packing. How that happens depends on your picking method, your order volume, and how your fulfilment space is set up.

A pick list or picking list is the document that guides this process. It tells the picker exactly what to collect, where to find each item, and how many units are needed to fulfil an order. This is also the term used on the Interparcel platform.

In most ecommerce businesses, picking lists are created automatically as soon as a customer places an order. They usually include product names, quantities, and the storage location for each item.

You might also hear picking lists referred to as a pick slip or picking slip. The name may vary, but the purpose is always the same: guide the picking process accurately and efficiently.

Once a picking list is created, the next question is how those orders are actually picked.

That’s where different picking methods come in.

Warehouse Order Picking Methods Explained

There are several ways to pick orders, and each method suits different order volumes, product types, and fulfilment setups.

Below are the most common warehouse order picking methods used by ecommerce businesses, starting with the simplest and progressing as operations scale:

- Single Picking: Best for simple, low-volume fulfilment.

- Batch Picking: Useful when handling growing order volumes with similar products.

- Cluster Picking: Ideal for managing multiple orders efficiently as volume increases.

- Zone Picking: Suited to larger warehouses with a wider product range.

- Wave Picking: Designed for high-volume operations with scheduled dispatch times.

- Waveless Picking: Built for fast-moving environments with continuos order flow.

Each method works differently depending on how your business operates. Below, we break down how each one works and when it makes the most sense to use it.

1. Single Picking (Also Called Discrete or Piece Picking)

Single picking means one picker handles one order at a time.

The picker collects all items for a single order, sends them to the packing area, and then moves on to the next order. It’s simple, easy to manage, and very accurate.

Many ecommerce businesses start here without even realising. As fulfilment becomes busier, teams often look for ways to pick more than one order per trip.

This method is best suited for businesses with low order volumes.

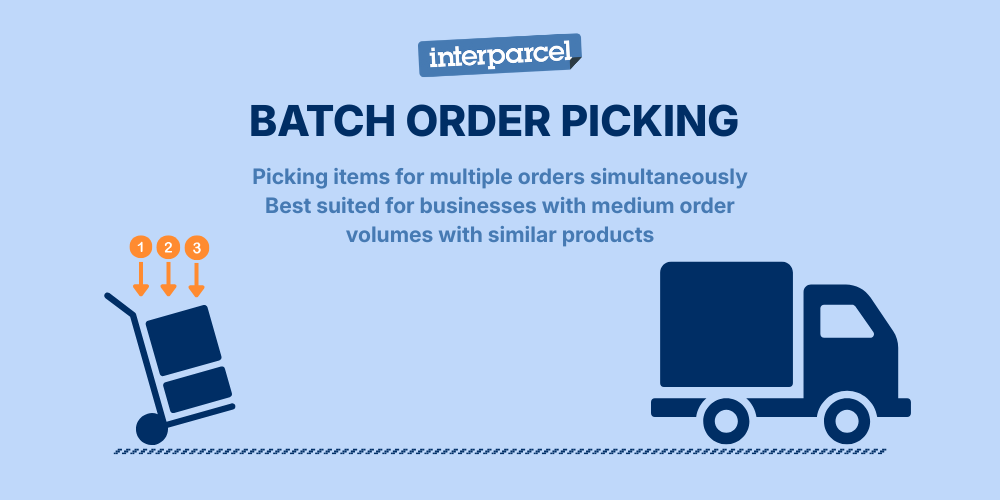

2. Batch Picking

Batch picking allows one picker to collect items for multiple orders at the same time.

Orders are grouped, often because they share similar products. The picker collects everything in one trip, and the orders are sorted and packed afterwards.

This reduces walking time and speeds up fulfilment compared to single picking, especially when many orders include the same items. To streamline the process further, some businesses move toward a more organised variation.

This method is best suited for businesses with medium order volumes that ship similar products.

3. Cluster Picking

Cluster picking is similar to batch picking, but with one key difference.

Instead of sorting orders after picking, cluster picking keeps orders separate during the pick itself.

The picker uses multiple containers, with each one assigned to a specific order. Items are placed directly into the correct container as they are picked. This helps maintain speed while keeping orders organised.

This method is best suited for businesses with medium order volumes looking to improve speed and accuracy.

If batch and cluster picking sound similar, you’re not alone…

The key difference comes down to when orders are separated.

Batch vs Cluster Picking

| Feature | Batch Picking | Cluster Picking |

|---|---|---|

| Orders picked together | ✅ | ✅ |

| Orders are kept separate during picking | ❌ | ✅ |

| Sorting is required after picking | ✅ | ❌ |

| Accuracy level | Moderate | Higher |

| Picking speed | Fast | Very fast |

| Best suited for | Similar products | Multiple small orders |

| Complexity | Low | Medium |

Once batch and cluster picking are clear, the next challenge many growing businesses face is managing distance and scale.

4. Zone Picking

Zone picking divides the warehouse into specific areas, or zones.

Each picker is responsible for a single zone and only picks items stored in that area. Orders move through multiple zones if they include products from different locations.

By keeping pickers focused on smaller areas, zone picking helps manage movement and workflow as fulfilment spaces grow. It is often combined with batch or wave picking to improve overall efficiency.

This method is best suited for businesses with high order volumes or larger fulfilment spaces.

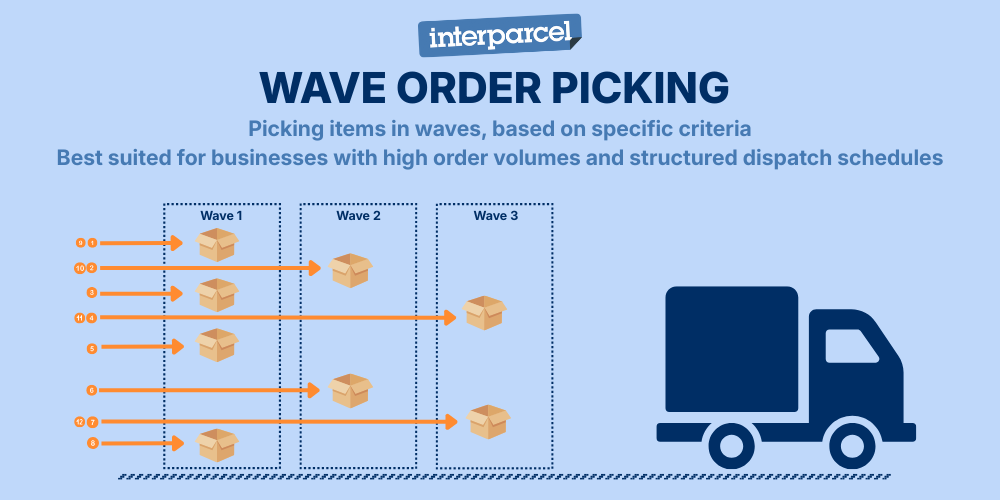

5. Wave Picking

Wave picking groups orders based on timing, priority, or shipping requirements.

Orders are released in scheduled waves, often aligned with carrier cut-off times, packing capacity, or dispatch windows. Picking then happens in a coordinated way across the warehouse.

Unlike batch picking, which groups orders by product similarity, wave picking focuses on when orders need to be shipped. This makes it a stronger option for operations with structured dispatch schedules.

This method is best suited for businesses with high order volumes and structured dispatch schedules.

6. Waveless Picking

Waveless picking removes fixed schedules entirely.

Orders are picked dynamically as they come in, with tasks assigned continuously rather than in planned waves.

This approach supports fast-moving ecommerce environments where order flow changes throughout the day. Systems and software play a key role in keeping the process organised and responsive.

This method is best suited for businesses with medium to high order volumes and fast-moving order flow.

Picking Technologies That Support These Methods

As order volumes grow, technology helps improve both speed and accuracy.

- Mobile scanners guide pickers through each task and confirm items in real time.

- Voice picking provides spoken instructions, keeping hands free.

- Pick-to-light systems use visual cues to show what to pick and where.

- Robotics and automation bring products to pickers instead of the other way around.

Most small and medium businesses start with basic scanning tools and introduce more advanced technology as their operations scale.

Technology supports picking methods, but it doesn’t replace the need to choose the right one.

That choice often comes down to order volume and growth stage.

Which Picking Method Is Right for Your Business?

The right picking method depends on how many orders you ship, what you sell, and how your fulfilment space is set up.

Here’s a simple way to think about it.

- Low order volume: Single picking keeps things simple and accurate.

- Growing order volume with repeat products: Batch or cluster picking reduces walking time and streamlines the process.

- Large product range or bigger warehouse: Zone picking helps manage distance and complexity.

- Strict dispatch times or carrier cut-offs: Wave picking keeps fulfilment aligned with shipping schedules.

- Fast-moving or unpredictable order flow: Waveless picking offers more flexibility.

Accuracy vs Speed: A Quick Reminder

Every picking method balances speed and accuracy in its own way.

- Single picking focuses on accuracy.

- Batch and wave picking focus on speed.

- Cluster and zone picking help balance both.

The right approach is the one that supports your current order volume and keeps fulfilment running smoothly as your business grows.

With that in mind, it becomes easier to see where your business fits today.

How Interparcel Supports Your Picking Process

Once you understand which picking method fits your business, the right tools can help support it and keep fulfilment running smoothly as order volumes grow.

From the Interparcel platform, you can download and print picking and packing lists designed to make the fulfilment process clearer and more efficient.

For businesses using scanners, Interparcel’s scanner tool allows you to choose what happens when you scan a picking list:

- Scan to Open: Loads the order into our Shipping Manager for review or edits.

- Scan to Book: Books the order and can automatically print the shipping label.

These tools are designed to support different picking methods by improving visibility, reducing manual steps, and helping teams move orders through fulfilment with greater confidence.

So, What Kind of Picker Are You?

Every ecommerce business uses a picking method, shaped by how orders come in and how fulfilment has grown over time.

- If you pack one order at a time, you’re using single picking.

- If you group similar orders, you’re using batch picking.

- If you pick several orders at once and keep them separate, that’s cluster picking.

- If your warehouse is split into areas, you’re using zone picking.

- If you organise fulfilment around dispatch times, you’re using wave picking.

- If orders are picked as they come in, you’re using waveless picking.

Each method works well in the right situation. The best picking method is the one that fits how your business runs today and continues to work as your order volume increases.

You now have a clear understanding of how your orders are picked and why that approach works for your business.

Are you affected by the Sendle service suspension? We have an immediate shipping solution for you!

Are you affected by the Sendle service suspension? We have an immediate shipping solution for you!

Facebook

Facebook Twitter

Twitter Instagram

Instagram Linked In

Linked In YouTube

YouTube